Key Takeaways

- Pogo pins are highly conductive connectors, using spring-loaded mechanisms and precious metal plating (like gold or nickel) to ensure low resistance and reliable electrical contact.

- Their construction with quality materials such as brass or copper alloys, combined with gold plating, provides excellent durability, corrosion resistance, and long-term performance.

- Pogo pins outperform many other connector types by offering stable conductivity through repeated cycles, low contact resistance (often below 50 milliohms), and resilience to temperature and humidity fluctuations.

- They are widely used in applications requiring frequent connection and disconnection, such as charging docks, PCB testing, wearables, medical, and aerospace devices.

- Selecting the right pogo pins involves considering material quality, plating thickness, spring force, mounting type, and environmental resistance to ensure consistent and efficient electrical connections.

Pogo pins are spring-loaded connectors found throughout modern electronics, from charging docks to test equipment. These small components create reliable electrical connections between devices using their spring mechanism. Understanding how Promax Pogo Pin connectors conduct electricity helps engineers choose the right components for applications requiring consistent, repeatable connections in consumer electronics, medical devices, and industrial testing equipment.

What Are Pogo Pins?

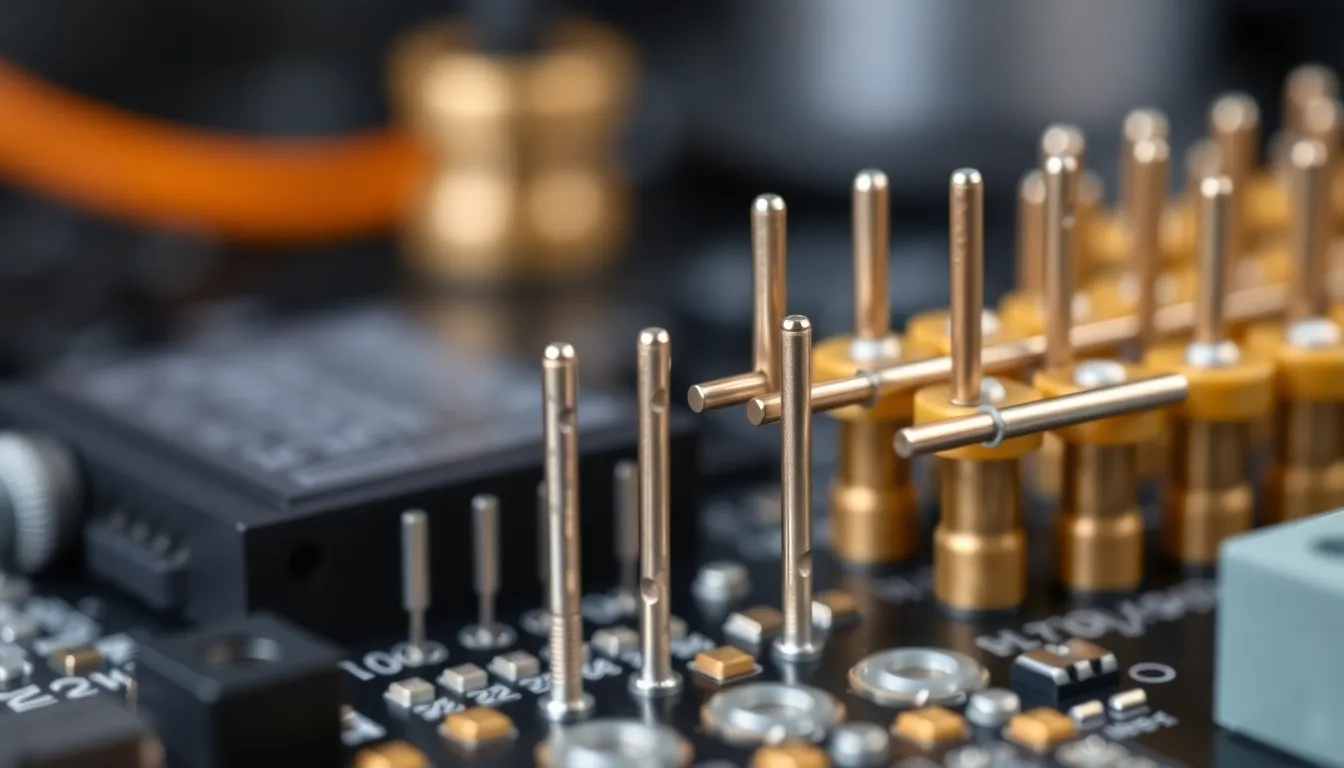

Pogo pins are spring-loaded contacts that enable temporary electrical connections between two electronic components. Each pogo pin features a plunger, barrel, and spring, which together maintain contact pressure and signal integrity during mating cycles. Manufacturers like Promax in China fabricate pogo pins with precision-machined brass or copper alloy bodies, ensuring low resistance paths for signal and power transmission.

Engineers specify pogo pins in applications demanding consistent, repeatable connections, such as battery charging bases, PCB testing jigs, and interface modules for medical and aerospace electronics. Typical designs offer travel ranges from 1 mm to 5 mm and withstand over 100,000 mating cycles. Contact plating such as gold, nickel, or palladium improves corrosion resistance and conductivity, critical for high-reliability assemblies.

Promax offers custom pogo pin and spring-loaded connector solutions, supporting pin counts from 1 to 100+ and customizable mounting options for surface mount, through-hole, or magnetic assemblies. These products achieve stable conductivity across temperature and humidity extremes, meeting quality requirements for advanced device integration.

How Pogo Pins Work

Pogo pins function as spring-loaded contacts that create stable conductive pathways between electronic circuits. Each pin maintains constant pressure, enabling reliable signal or power transfer even in repeated applications.

Electrical Connectivity Explained

Pogo pins establish electrical conductivity through metal-to-metal contact, using a plunger, barrel, and internal spring. The spring pushes the plunger against a mating surface, ensuring a low-resistance connection. Promax engineers optimize the force exerted by the spring, keeping contact stable through vibration and movement. Shielded pogo pin arrays reduce crosstalk in high-density settings, with signal integrity maintained from gold plating, controlled tolerances, and calibrated contact resistance, consistently measuring below 50 milliohms in production units. Designers select pogo pin connectors for data, charging, or test points where repeated cycling, compact pitch, and low insertion force are critical.

Materials Used in Pogo Pins

Manufacturers use high-conductivity metals like brass or phosphor bronze as the base for pogo pin components. Promax specifies gold or nickel plating for the external surfaces, improving corrosion resistance and electrical conductivity. The spring typically uses stainless steel, chosen for fatigue resistance and mechanical stability after 100,000+ cycles. Contact finish thickness, usually 10–50 microinches for gold, increases wear resistance while lowering surface resistance. Promax runs precise electroplating lines, controlling layer uniformity to guarantee quality. Assemblies meet device requirements for wear, current load, and environmental exposure, supporting applications from consumer electronics to medical instrumentation.

Are Pogo Pins Conductive?

Pogo pins create reliable conductive paths between electronic components in products needing frequent connection and disconnection. Conductivity results from the direct metal-to-metal contact established when the spring-loaded tip presses against the mating pad.

Factors Affecting Conductivity

Material selection directly affects pogo pin conductivity. Manufacturers like Promax use copper alloys, brass, or phosphor bronze for pin cores as these metals offer low resistance for efficient current flow. Gold or nickel plating minimizes surface oxidation and ensures stable electrical contact through 100,000+ cycles. Spring force keeps constant pressure, maintaining consistent conductivity even if subject to vibration or repeated movement. Contaminants, humidity, or surface debris may reduce contact quality, so Promax maintains high plating thickness and tight dimensional tolerances. Environmental testing at Promax confirms that pins deliver stable performance in high-humidity and variable-temperature environments from −40°C to +85°C.

Comparison With Other Connectors

Pogo pins create lower and more stable contact resistance than most friction or blade connectors due to their precise spring mechanisms and fine-tuned plating processes. For example, a typical pogo pin from Promax offers contact resistance below 50 milliohms, enabling efficient signal transmission at current ratings from 1A to 5A, depending on pin size. In contrast, standard spring clip or leaf connectors may exhibit fluctuating resistance under vibration. Unlike rigid soldered pins, pogo pins enable repeatable temporary connections, reducing wear on mating surfaces. Promax designs pogo pins for high cycle durability, maintaining conductivity across thousands of insertions, where other connector types might fail or need replacement.

Common Applications for Conductive Pogo Pins

Electronics manufacturers use conductive pogo pins for device charging, signal testing, and modular connections. Charging bases in consumer electronics, like smartphone docks and true wireless earbuds, rely on spring-loaded pogo pins for rapid, low-resistance power transfer. Test engineers apply pogo pin contacts in automatic test equipment (ATE) for printed circuit board (PCB) testing, with each pin providing reliable, repeatable signal connections for high-speed diagnostics.

Medical device developers select pogo pin arrays for modular sensor modules and diagnostic pads, where stable conductivity prevents data loss during device use or sterilization cycles. Aerospace suppliers integrate robust pogo pin solutions into avionics modules and sensor harnesses, enabling multi-cycle reliable connections even in vibration-prone environments.

Promax in China manufactures spring-loaded contacts and custom connector arrays meeting industry requirements for durability and conductivity. The company’s pogo pins are available with gold plating for low contact resistance, custom pin counts for battery contacts, and waterproof housing for harsh-environment equipment. Engineers request Promax’s precision pogo pin designs for wearables, smart cards, and IoT systems, leveraging stable electrical paths and high mating cycle performance essential for product reliability.

| Application Area | Pogo Pin Function | Example Use Case |

|---|---|---|

| Consumer Electronics | Charging, Data Sync | Wireless earbud charging case |

| PCB Testing | Temporary electrical connection, Signal test | ICT and FCT testing jigs |

| Medical Devices | Sensor contact, Modular connectivity | ECG pads, detachable probes |

| Aerospace | Rugged, repeatable circuit-to-circuit connection | Aircraft sensor module |

| Wearables/IoT | Low-profile, high-cycle interconnect | Smart wristband battery pads |

Promax’s manufacturing processes guarantee spring force consistency, surface finish quality, and low resistance—even in miniaturized designs for high-density device integration.

Considerations When Using Pogo Pins

Consider material selection for pogo pin conductivity, as alloys like copper, brass, and beryllium copper paired with gold plating consistently deliver low contact resistance, typically under 50 milliohms in precision designs from Promax. Evaluate spring force and durability, keeping in mind that consistent spring pressure ensures stable connections across thousands of cycles, with Promax pogo pins often rated >100,000 actuations under mechanical and thermal stress.

Assess mounting and tolerance requirements; Promax offers pogo pins in SMD, through-hole, and custom PCB footprints, maintaining tolerances within ±0.05 mm for reliable mating in high-density applications. Environment conditions such as temperature, humidity, and potential exposure to corrosion impact long-term contact stability; Promax supplies pins with IP67 sealing and anti-corrosive plating for medical, industrial, and outdoor devices.

Minimize crosstalk and signal degradation by selecting shielded pogo pin arrays, as these configurations support clean transmission in multi-pin layouts found in test equipment and communication dongles. Ensure cleaning access, since debris or oxidation on contact surfaces may raise resistance and affect performance if not routinely addressed, especially in test or docking applications.

Verify compliance with industry standards for high-reliability sectors; Promax manufactures pogo pins meeting automotive, medical, and aerospace certifications and provides material traceability for mission-critical assemblies.

About Promax

Promax, located in Gary, IN, specialises in manufacturing high-quality pogo pins, spring-loaded connectors, and magnetic connectors for various industries, including consumer electronics, aerospace, and medical.

Led by Manager Gavin, Promax has over 15 years of experience in providing customizable solutions tailored to the specific needs of clients. With a focus on competitive pricing and internationally certified quality standards, Promax delivers reliable and precision-engineered products that meet the highest standards of performance.

Contact:

Gavin, Manager

Phone: (765) 705-7361

Email: [email protected]

Address: 480 Jackson St, Gary, IN 46402, USA

Website: www.promaxpogopin.com (if applicable)

Frequently Asked Questions

What are pogo pins?

Pogo pins are small spring-loaded connectors used to create temporary electrical connections between devices. They consist of a plunger, barrel, and spring, and are commonly found in charging docks, test equipment, and modular electronic assemblies.

How do pogo pins provide reliable conductivity?

Pogo pins maintain constant contact pressure through their spring mechanism, ensuring a stable metal-to-metal connection. This design minimizes contact resistance and supports reliable signal or power transfer even under vibration or movement.

What materials are used in pogo pins for best conductivity?

High-conductivity metals, such as copper alloys and brass, are often used for pogo pins. These are usually plated with gold or nickel to lower contact resistance and prevent corrosion, ensuring optimum electrical performance over many cycles.

What are common applications of pogo pins?

Pogo pins are widely used in device charging bases, PCB testing jigs, medical sensors, aerospace modules, wearables, smart cards, and IoT devices. Their ability to provide stable temporary connections makes them essential in various industries.

How many cycles can high-quality pogo pins withstand?

High-quality pogo pins can handle over 100,000 mating cycles. Their precise spring mechanisms and durable materials help maintain performance and reduce wear even with frequent use.

How do pogo pins compare to other connectors in terms of resistance?

Pogo pins typically offer lower and more stable contact resistance than other connector types, such as friction or blade connectors. This makes them especially valuable for applications requiring consistent signal quality over many cycles.

What should I consider when selecting pogo pins for my application?

Key factors include the pin’s material and plating for conductivity, required spring force, operating environment (such as exposure to moisture), mounting style, and compliance with industry standards. These factors ensure long-term stability and reliable performance.

Can pogo pins be used in harsh environments?

Yes, pogo pins can be designed with gold plating, waterproof housings, and anti-corrosive coatings (like IP67 sealing) to withstand moisture, dust, and temperature extremes, making them suitable for wearables, outdoor devices, and industrial applications.

How do shielded pogo pins reduce electrical interference?

Shielded pogo pins use protective barriers to minimize crosstalk and signal noise, especially in high-density electronic assemblies. This ensures cleaner signal transmission and better performance for sensitive applications.

Where can I get custom pogo pin solutions?

Manufacturers like Promax offer custom pogo pin solutions tailored to specific pin counts, sizes, mounting styles, and environmental requirements. These customizations help meet the exact needs of advanced electronics projects.